Flexible staple fiber making machine production line produce both hollow and solid fiber

Suzhou soft gem intelligent equipment Co.,Ltd have 30 years experience in overall solution of producing of Chemical fiber, We can provide general contract (turnkey)service of direct spinning polymerization project, recycled bottle flakes cleaning line, chemical fiber production line, intelligent storage and so on, including the whole project planning, process package and engineering design, complete equipment manufacturing, digital information integration,and

after-sale services.

Main products:

1. Production line of 3 Dimensional hollow crimp PET staple fiber

2. Production line of high tenacity PET staple fiber

3. Flexible Production line of both hollow and solid PSF

4. Production line of eisai composite staple fiber

5. Production line of low melting composite staple fiber

6. Production line of PLA staple fiber

7.Production line of other staple fiber

- Overview

- Related Products

Product details description

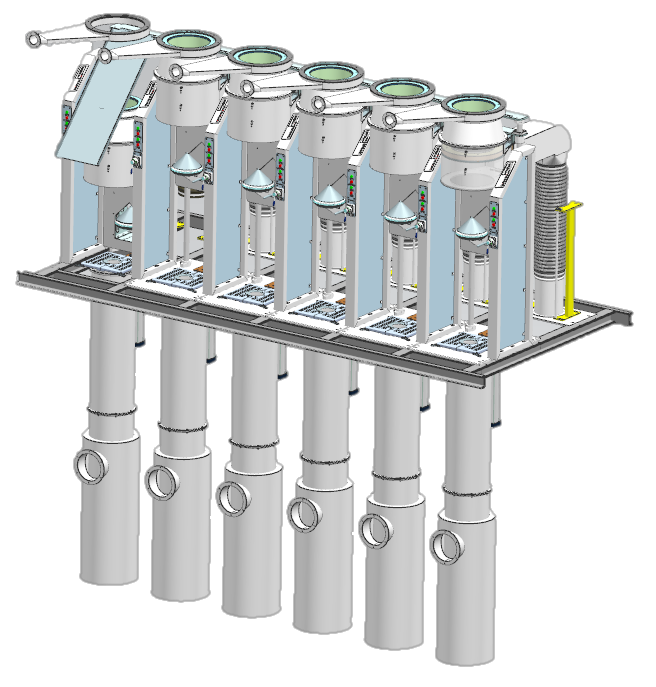

Hollow fiber producing Process description

Spinning Line

PET raw material conveying→Drying→Screw extruder→Filter equipment→Spinning beam→Spinning metering pump→Spin pack→Tow quench→Winding and oiling→Traction machine→ feeder→Can Reciprocating machine →Tow can conveying

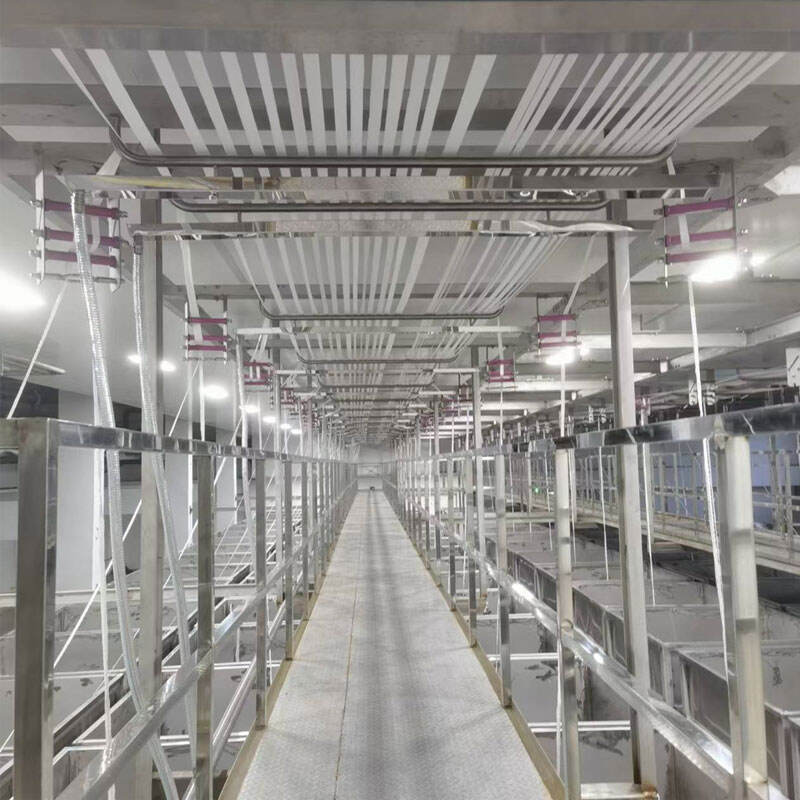

Drawing Line

Creel stand→Tow guild frame→Tow guide stand→Dip oil bath→Drawing machine I→Spray immersion draw chest→Drawing machine II→Steam heating box→Draw stand Ⅲ→Oiling machine→Tow stacking→Steam preheating box→Crimper→ laying machine →Catcher→Spray oiling machine→Traction tension machine →Cutting machine→Sway machine→relaxed heat setting→Fiber conveying→baling press

Solid fiber(high tenacity) producing Process description

Spinning Line

PET raw material conveying→Drying→Screw extruder→Filter equipment→Spinning beam→Spinning metering pump→Spin pack→Tow quench→Winding and oiling→Traction machine→ feeder→Can Reciprocating machine →Tow can conveying

Drawing Line

Creel stand→Tow guild frame→Tow guide stand→Dip oil bath→Drawing machine I→Spray immersion draw chest→Drawing machine II→Steam heating box→Annealer→Oiling machine→Drawing machine III→Tow stacking→Steam preheating box→Crimper→Sway machine→relaxed heat setting→Catcher→Tension frame→Cutter→baling press

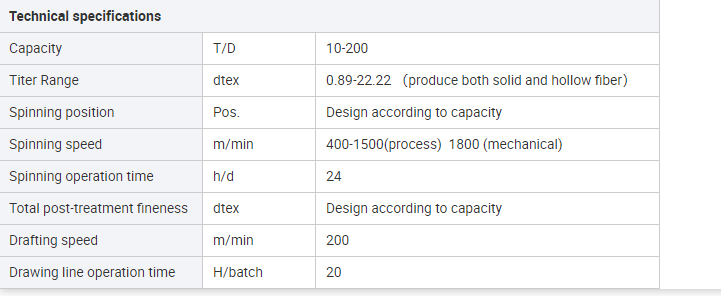

Product parameter list

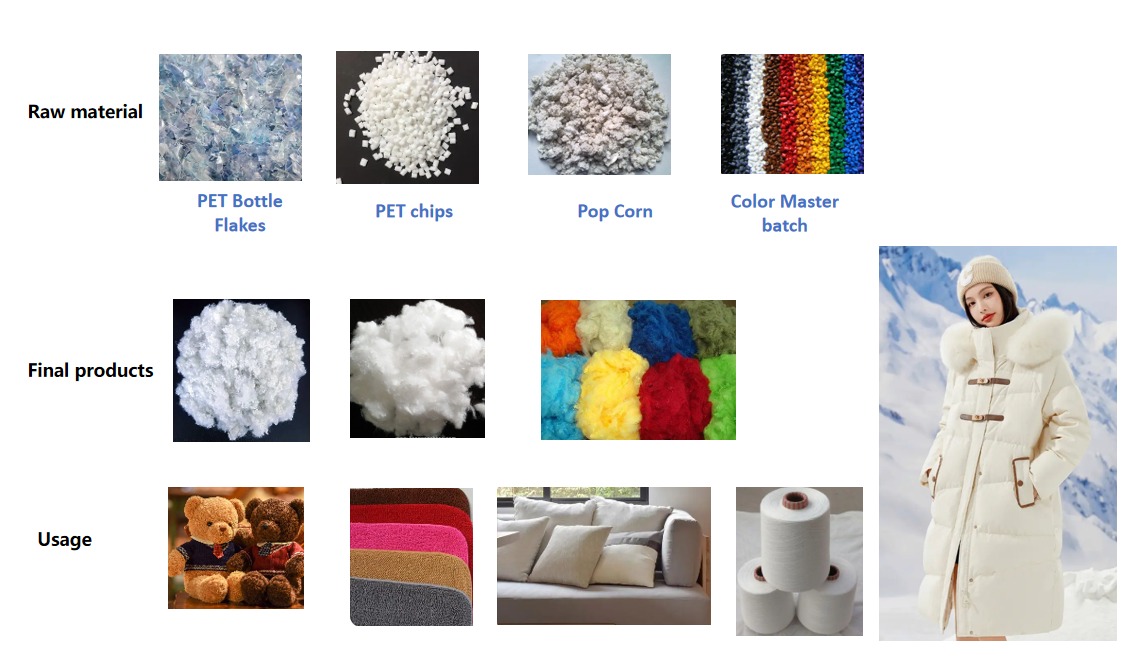

Product application diagram